CEBA has been created more than 35 years ago with the aim to serve all the industries where the heating technology is the most important part of the process.

The long experience in design of high tech burners together with the deep knowledge of metallurgical processes make CEBA a leader in the combustion field in different industries, particularly in Iron&Steel and Oil&Gas with several successful experiences in France.

CEBA joined together with ESPATHERM creating CEBA FRANCE ESPATHERM (CFE) because it recognizes its characteristic qualities in the history of Espatherm: passion, dedication to work, attention to the customer, flexibility and customer service.

CEBA with its subsidiary in France, CFE, guaranteed the continuity of Espatherm's activity in the field of heat treatment tecnology, the assistance to its historical customers and the continuos development of new applications.

CFE will guarantee the maintenance and the assistance of all ESPATHERM equipment.

Ceba France Espatherm (CFE) designs and produces in cooperation with CEBA a large variety of heat treatment furnaces for steel industry.

Thanks to their experience in the combustion field and metallurgical process, this partnership led to an improvement of the existing products and to the development of new solutions in compliance with the latest requirements in terms of technology, efficiency and environmental impact.

CFE and CEBA can provide a complete turn-key system, following the process from the design to the after sales services and spare parts supply.

The accurate attention to Customer's need, the modular construction and the high specialization of engineers make CFE a reliable partner for heat treatment equipments.

Temperature: 600 ÷ 1250°C

Class 4 +/- 10°C according to AMS 2750

Thermal power: 4.500 kW

Internal dimensions: 11.000 x 2.000 x 1.500 mm

Maximum load: 50T

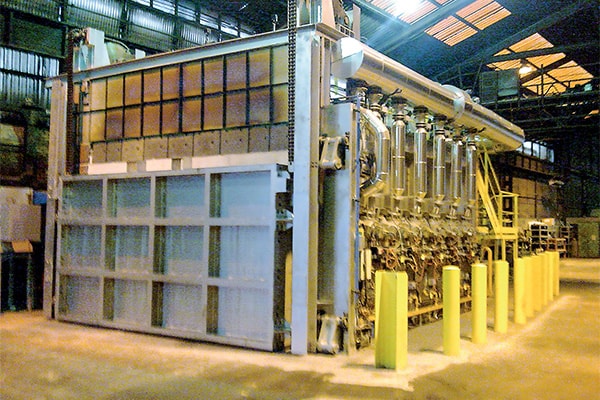

Temperature: 700 ÷ 1280°C

Class 2, +/- 6°C according to AMS 2750

Thermal power: 10.800 kW

Internal dimensions: 12.000 x 3.500 x 1.600 mm

Load: 200T

Burners type: regenerative with flox feature

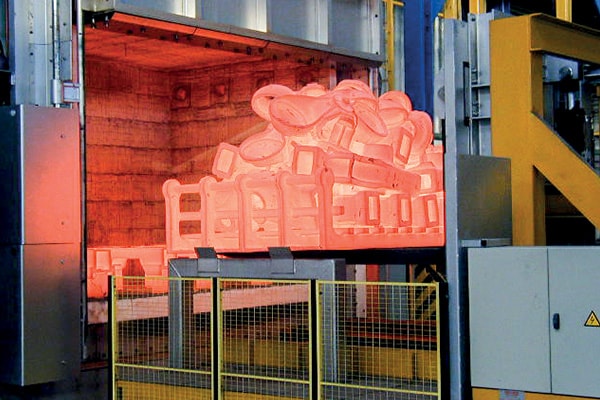

Temperature: 350 ÷ 1.280°C

Class 4, +/- 10°C according to AMS 2750

Thermal power: 6.000 kW

Internal dimensions: 6.400 x 3.000 x 1.500 mm

Load: 90T

Burners type: regenerative with flox feature

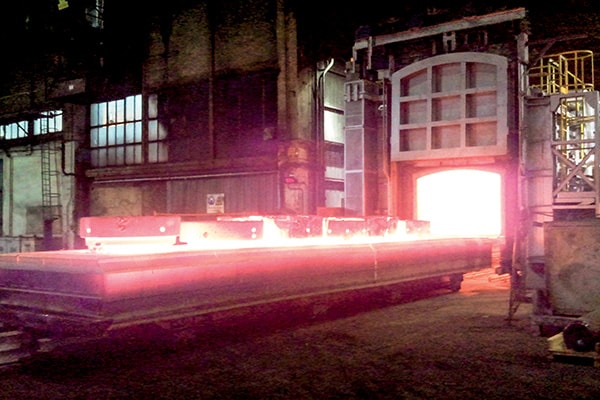

Temperature: 1.050 ÷ 1.280°C

Class 5, +/- 14°C according to AMS 2750

Thermal power: 3.900 kW

Internal dimensions: 3.400 x 4.000 x 1.050 mm

Load: 30T

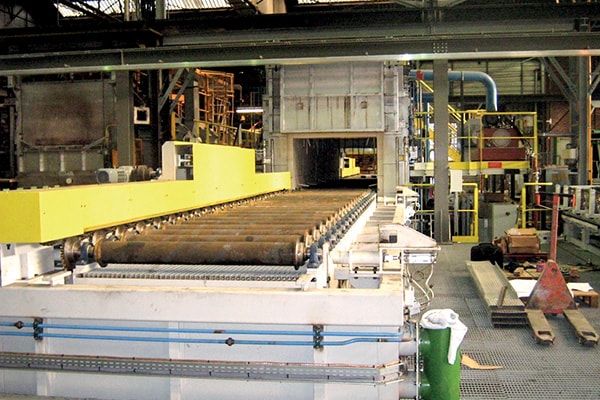

Temperature: max 1.050°C

Thermal power: 4.680 kW

Useful internal volume: 9.010 x 7.200 x 400 mm

Internal dimensions: 50T

Burners type: autorecuperative with flox feature

Temperature: 500 ÷ 1.280°C

Class 4, +/- 10°C according to AMS 2750

Thermal Power: 1.500 kW

Internal dimensions: ø3.240 x 700 mm

Maximum load: 5T

Temperature: 200 ÷ 1.100°C

Class 2, +/- 6°C according to AMS 2750

Thermal Power: 1.160 kW

Internal dimensions: 2.350 x 3.310 x 2.430 mm

Temperature: 800 ÷ 1.120°C

Class 4, +/- 10°C according to AMS 2750

Thermal power: 2.300 kW

Internal dimensions: 8.000 x 1.250 x 900 mm

Maximum Load: 8T

Temperature: 880°C

Class 2, +/- 5°C according to AMS 2750

Thermal power: 300 kW

Internal dimensions: 1.300 x 1.400 x 8.500

Load: 1.250kg

Features:

Temperature: 600 ÷ 860°C

Class 2, +/- 5°C according to AMS 2750

Thermal power: 250 kW

Loading type: INOX and Nickel alloyed

Feature: electric resistances