Burners are the heart of any fired heater and furnaces in the refining, petrochemical and chemical process industries.

CEBA is constantly researching & developing cutting edge solution for Oil & Gas burners to reach best performances and lowest emission in force of the world’s best available technology and in terms of reliability and efficiency.

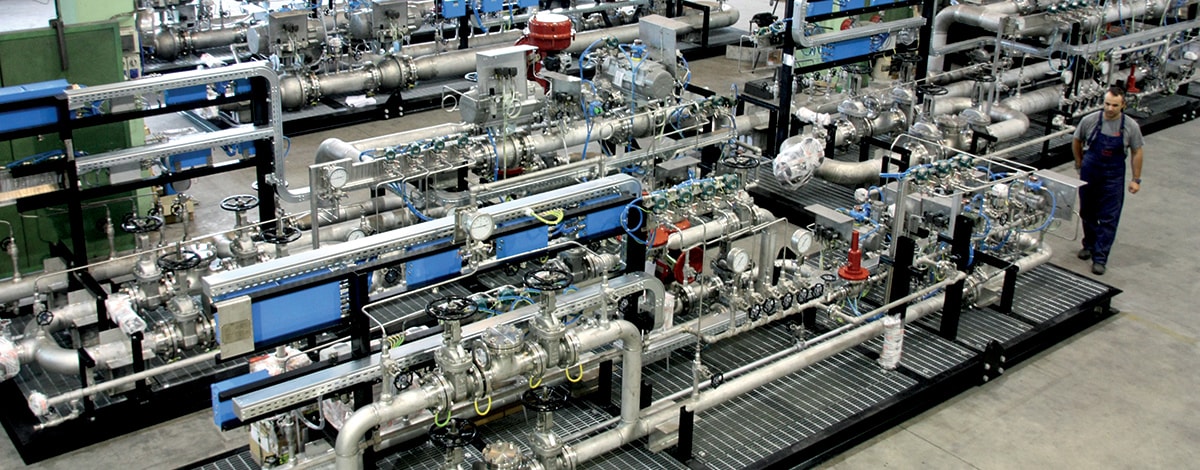

CEBA manages the whole production process, from engineering to final product manufacturing.

Burners are designed according to API 535 standards and can be customized to fit customers’ request.

CEBA design a broad range of conventional burners, low NOx and ultra low-NOx process burners.

CEBA burners’ design allows the use of a wide range of fuel gases – such as natural gas, waste gas and light, medium or heavy oils – to be fired either on their own or in combination. The combustion air can be supplied to the burner in natural draft or forced draft modes. Depending on the furnace and on the heater, different flame shape may be required to properly operate, such as flat or round.

CEBA design burners which provide the heat needed for the chemical reaction in the reformer and in the Ethylene Cracking Furnaces.

CEBA is providing latest technology in the design of the following burners applied in main petrochemical application:

CEBA is the sole company entitled to produce and sell all the original spare parts of the burners provided since 1960.

CEBA can supply a wide range of spare parts including but not limited to MAC burners, round-burners and flat flame burners in the MOV series burners, gas nozzles, tips, jets and oil atomizer, complete gas gun, oil gun (SAO), burner refractory, complete pilot, ignition system and ancillaries.

CEBA can also support the customer in the revamping of the existing plants replacing the old burners with new ones, reaching higher performances and lower NOx emissions.

The burners design can be customized in order to be installed on the existing heaters reducing as much as possible the required modifications.