CEBA is committed to reducing carbon dioxide emissions through several strategies:

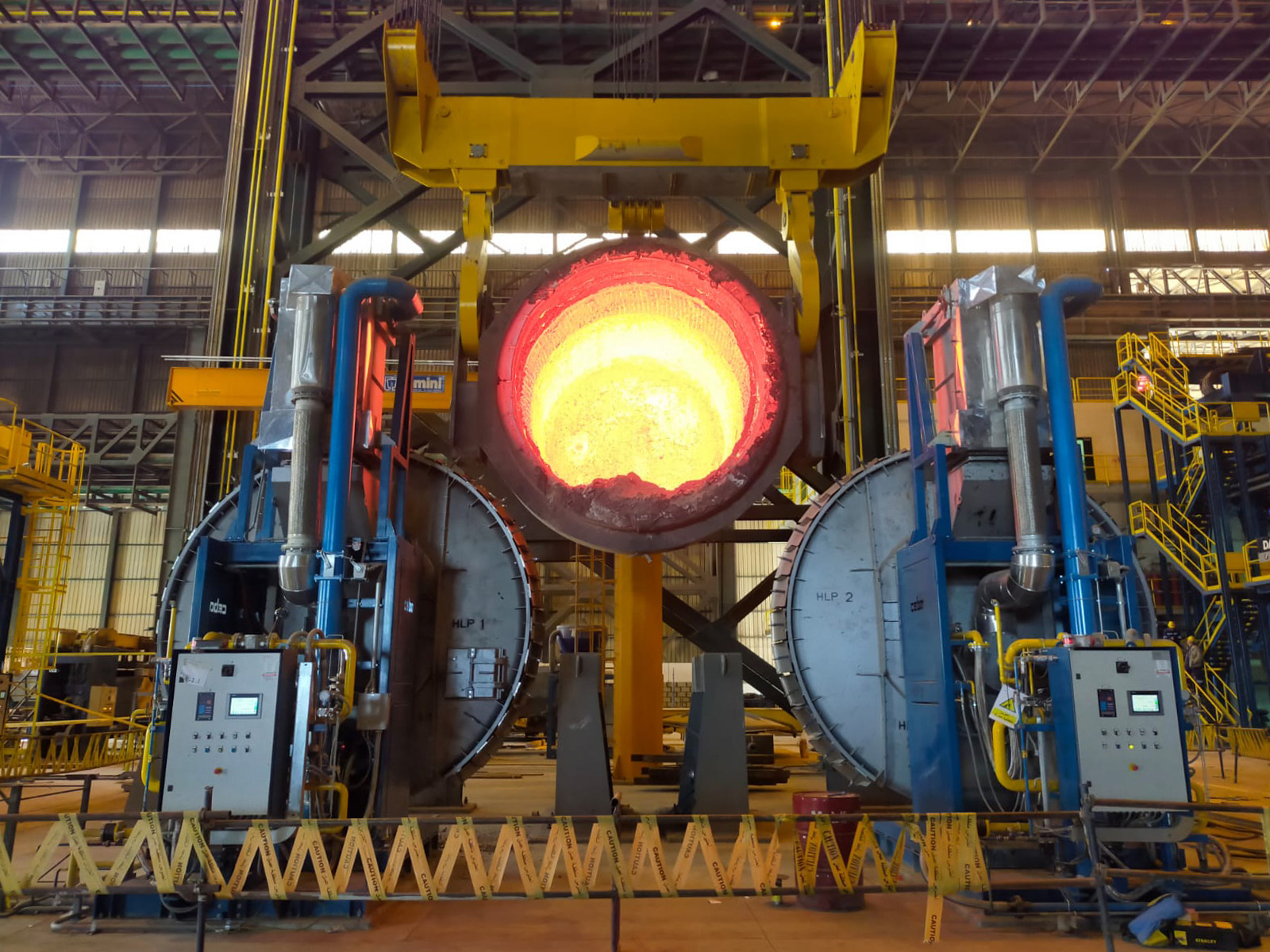

CEBA develops and supplies equipment with advanced systems for energy efficiency and fuel gas consumption reduction. These technologies, including air-gas combustion (recuperative and regenerative) and oxygen-gas combustion, contribute to substantial gas savings. They can be implemented in new equipment as well as retrofitted into existing installations.

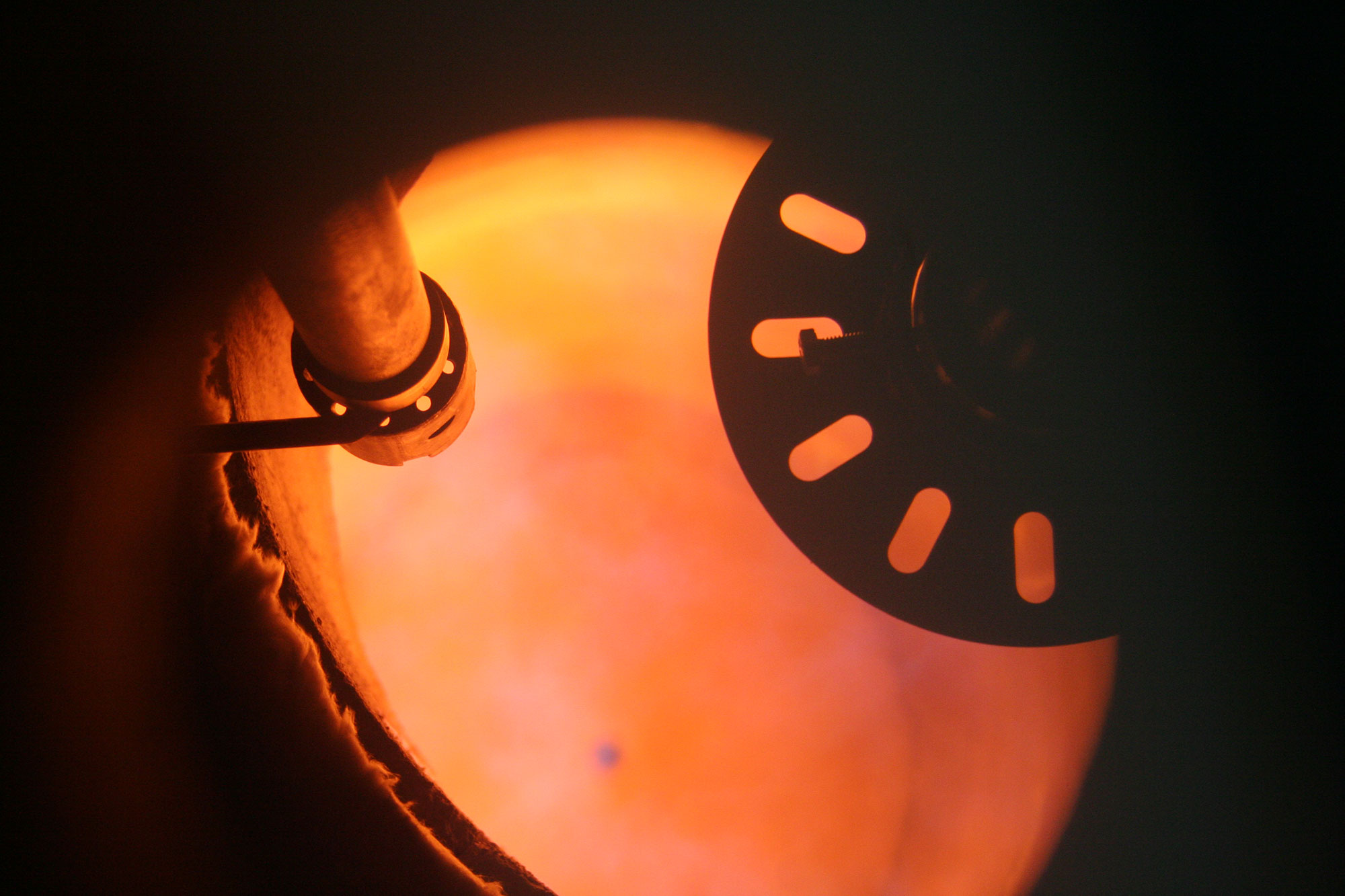

Building on its extensive experience in hydrogen combustion within the Oil & Gas industry, CEBA has designed and produced burners for the Iron & Steel sector. These burners are capable of operating with a mixed gas composed of methane and hydrogen, with a variable content ranging from 0% to 100%. This flexible design allows customers to adjust the methane and hydrogen ratio in real-time, catering to their specific fuel requirements.

CEBA is expanding its portfolio by introducing electrical heating systems as an alternative to combustion in various applications. This includes ladle and tundish preheaters, furnaces as well as regenerative thermal oxidizers. By embracing electric heating, CEBA aims to reduce reliance on fossil fuels and promote cleaner energy alternatives.

CEBA offers equipment equipped with low NOx and ultra-low NOx burners that adhere to the most stringent regulations, ensuring minimal nitrogen oxide emissions.

CEBA supplies regenerative thermal oxidizers to diverse industries, facilitating the removal of various pollutants (such as VOCs, H2S, CO, odors, and other oxidizable compounds) from process gases. By deploying these systems, CEBA helps industries significantly reduce their emissions, ensuring better air quality and environmental protection.

CEBA implements decoating technology, a thermal treatment based on pyrolysis, to remove contaminants such as paper, oil, links, paint, and plastic from aluminum scrap. This treatment process enhances the cleanliness of the recycled aluminum, making it suitable for the production of new aluminum products. By reducing metal losses and production costs, CEBA actively contributes to sustainable recycling practices and the circular economy.