Since more than 35 years CEBA has been one of the pioneers in the research and development of new solutions for ladle preheaters to increase efficiency, reduce the fuel consumption and achieve the lowest emissions.

According to machine operation, CEBA is in the position to propose and supply the most suitable and convenient solution

to satisfy the Customer’s needs, including retrofit of existing machines.

All the machines are equipped with proprietary design burner developed by CEBA specifically for ladle preheaters, low NOx and ultra-low NOx design, already capable to work with premixed H2-CH4.

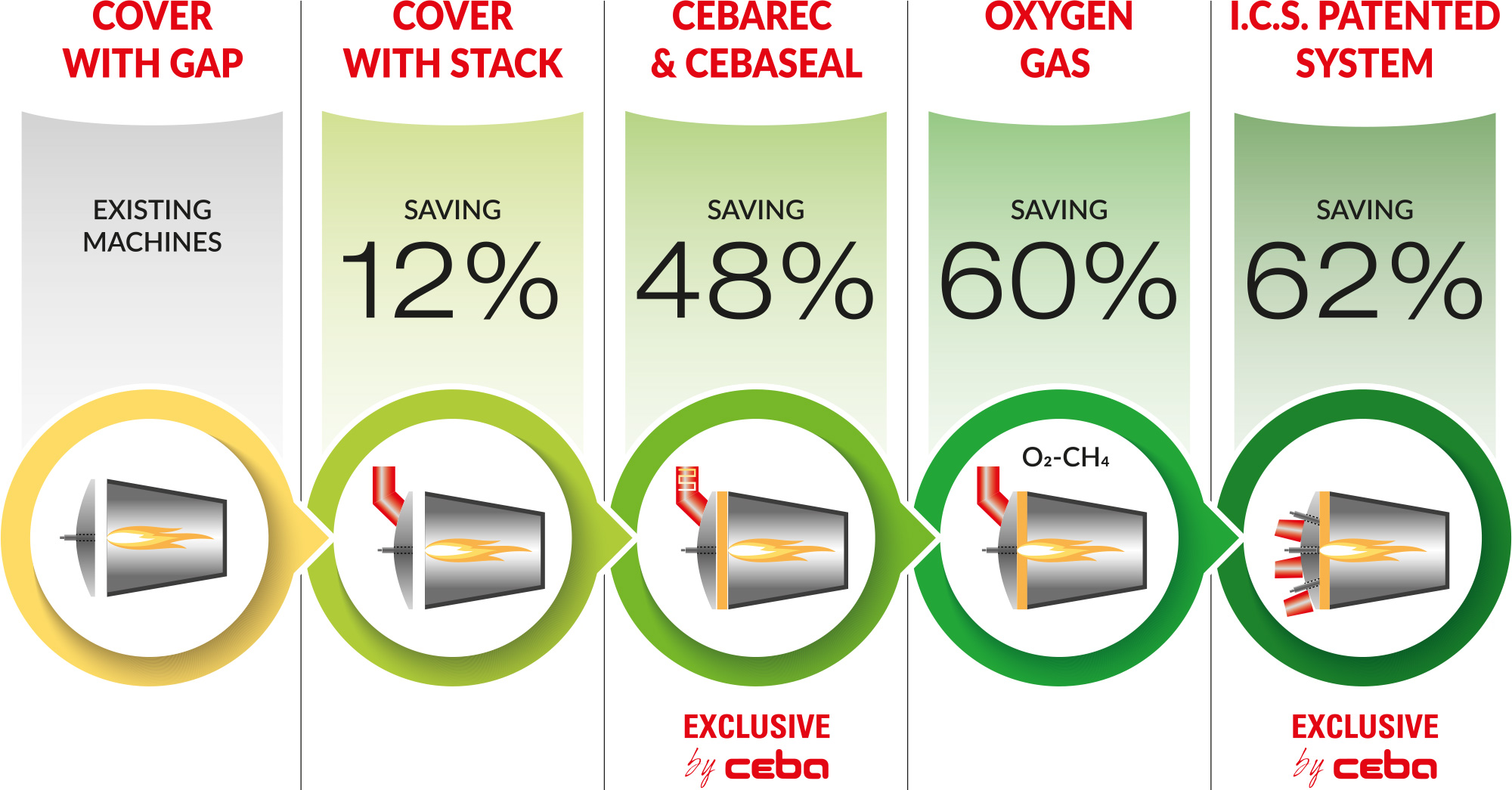

The current portfolio includes several solutions to reduce the fuel gas consumption, taking advantage of the latest available technology for air-gas combustion (recuperative and regenerative) and oxygen-gas burners.

The main goal is to recover the heat remaining in the hot flue gases, carrying them out at the lowest possible temperature.

CEBA has designed a high efficiency heat exchanger named CEBAREC to recover the maximum heat from the fumes. Hot flue gases coming out from the ladle are collected and sent to the CEBAREC where they transfer their heat to the fresh combustion air. The more the temperature of combustion air is increased, the more the fuel gas consumption is reduced. To better convey the exhausts to the CEBAREC and reduce losses around the edge of the ladle, CEBA has designed a zero-gap system made in high temperature resistant stainless steel named CEBASEAL (patent pending). The combination of CEBASEAL & CEBAREC allows to reach a temperature of combustion air higher than 450°C.

CEBA has developed oxygen-gas burner specifically for the ladle preheaters, designed to reach lowest NOx and CO2 emissions and the highest efficiency.

Burner is realized in high temperature resistance stainless steel and it is air cooled to increase its lifetime.

Machine is designed to comply with the latest standards including safety and SIL requirements.

For ladle dryers CEBA has realized an integrated burner capable to work in air-gas mode at lowest temperature and slow heating

and in oxy-gas mode during preheating and holding at high temperature

ICS is an innovative regenerative burner technology, patented by CEBA, which guarantees the maximum results in terms of efficiency and energy saving. Hot flue gases coming out from the ladle are collected and sent to the regenerative system where they transfer their heat to the fresh combustion air. Up to 62% of the fuel gas consumption can be reduced preheating the combustion air temperature above 900°C, i.e. recovering more than 85% of residual heat contained in the flue gases. Differently from any other regenerative system available on the market, ICS is designed in order to guarantee continuous flame presence and a modulating heat release according to the required heating cycle.